3D PRINTING

Processes

Fused Deposition Modeling

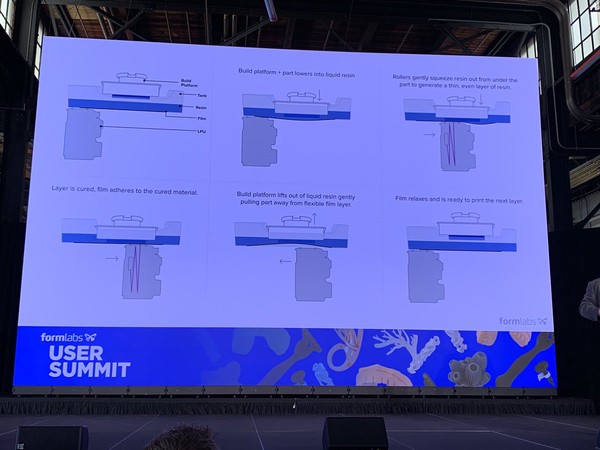

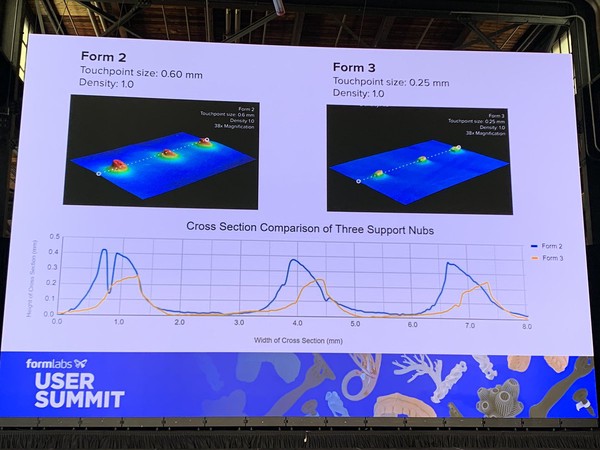

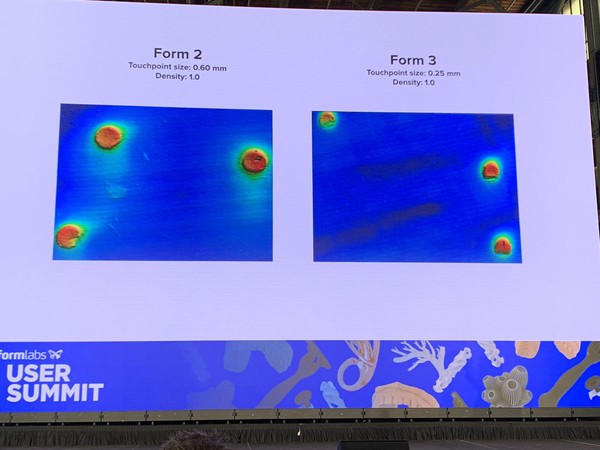

Stereolithography (SLA)

Post-processing

Cleaning

Most of my experience here is with Formlabs’ clear resin.

- Dedicate a wash bucket to each resin. Fill it with Isopropyl alcohol (IPA), which dissolves liquid resin.

- Rinse parts in multiple stages

- First stage of washing can result in some resin, diluted in IPA, coating the surfaces of the parts. Once the IPA evaporates all thats left is the resin and so the parts feel tacky

- Best to immediately wash again so that the resin doesn’t cure at all under ambient light

- Let parts dry for about 30 minutes

Formlabs

Materials

- Flexible Resin 1L has been good enough to hold liquid during some deflction testing

2019 user summit

Optical barriers

- Renshape XL (or soemthing) has a glossy side which can be nice.

Origin & Loctite 3843

Machine-specfifc

Ultimaker S5

I’ve had really good success with an Ultimaker S5 printing and using Cura as a slicer

Material

- 1612/9015 3D Printer Filament, 2.85mm Dia, Silver, PLA, 145 to 160 °C

Settings

- Quality

- Layer height = 0.1 mm

- Shell

- Wall Thickness = 1 mm

- Wall Line Count = 3

- Top/Bottom Thickness = 1mm

- Top Thickness = 1mm

- Top Layers = 10

- Bottom Thickness = 1 mm

- Bottom Layers = 10

- Top Thickness = 1mm

- Horizontal Expansion = 0 mm

- Wall Thickness = 1 mm

- Infill

- Infill Density = 20%

- Infill Pattern = Triangles

- Material

- Printing Temperature = 200C

- Build Plate Temperature = 60C

- Speed

- Print Speed = 70 mm/s

- Travel

- Enable Retraction = True

- Z Hop When Retracted = True

- Cooling

- Enable Print Cooling = True

- Fan Speed = 100%

- Support

- Generate Support = True

- Support Extruder = Extruder 1

- Support Placement = Everywhere

- Support Overhang Angle = 60

- Build Plate Adhesion

- Enable Prime Blob = False

- Build Plate Adhesion Type = Brim

- Build Plate Adhesion Extruder = Extruder 1

- Dual Extrusion

- Enable Prime Tower = True

- Prime Tower X Position = 294.76 mm

- Prime Tower Y Position = 206.76 mm