LASER DIRECT STRUCTURING

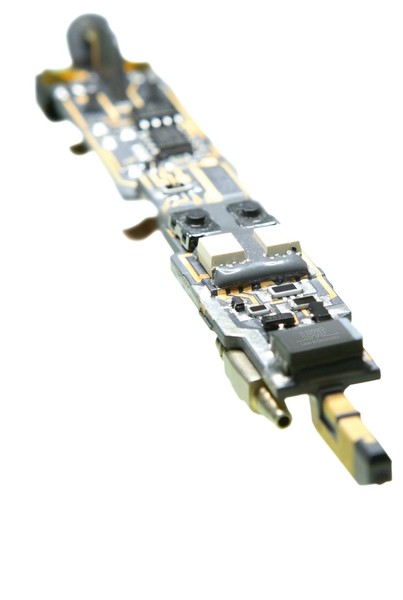

Laser Direct Structuring (LDS) or 3-Dimensional Molded Interconnect Devices (3D-MID) refer to a process where metal can be plated selectively on a plastic. Commonly used for antennas.

Suitable Materials

Vectra 840i or whatever.If you want to SMT on LDS part you need something with high heat resistance

Design Guidelines

| Category/Feature | Description of design guideline | Image |

|---|---|---|

| Vias | 1. wall thickness 300 μmmax2. hole diameter 300 μm min3. angle 50° min4.wall thickness 600 μm max. |  |

| Plating | Chemical copper plating should be less than 8um | |

| Vestige | Injection gate should not be on the pattern area and at least 0.2mm away from LDS pattern. If this is not possible, the ejection pins must have 30° degree angle and the flash form should be less than 0.05 mm |  |

| Edge radius | Recommended > 150μm |  |

| Distance to wall | Recommended > 150μm |  |

| Distance to edge | Recommended > 150μm. This is very critical if pattern is needed on side face. Can maybe go less if there is no cosmetic requirements. |  |

Suppliers

These companies provides MID contract manufacturing capabilities using LPKF laser direct structuring technology from in North America. Their services include engineering support, injection molding, laser structuring and metallization which allows for excellent turnaround.

| Company | Location | Contact |

|---|---|---|

| Amphenol-mcp | Lincolnshire, IL 60060 | Dan Gorsage Phone: (847) 601-6717 Dan.gorsage@amphenolmcp.com |

| Harting | Eglin, IL 60123 | Greg Whiteside Phone: 847-249-0460 Greg.Whiteside@HARTING.COM |

| Molex | Lisle, IL 60532 | Colm Conlon Phone: (630) 718-5122 Colm.Conlon@molex.com |

| Multiple Dimensions | Minneapolis MN 55408 | Will Slade Phone: 612-728-5807 will.slade@multipledim.com |

| TE Connectivity | Aptos, CA 95003 | Frank Basile Phone: (408) 234-7737 fjb@tycoelectronics.com |

| 2E Mechatronic | ||

| Beta LAYOUT GmbH | ||

| Changshu Honglin | ||

| Chengdu Homin | ||

| Ebina Denka Kogyo | ||

| Ethertronics | ||

| Goertec Inc | ||

| Hahn Shickard | ||

| Janus Precision | ||

| MID-TRONIC | ||

| S2P Smart Plastic Products | ||

| Shenzhen Sunshine | ||

| TEPROSA GmbH |